What causes clay to explode in the kiln is a question many potters face, often due to the material’s natural properties interacting with improper techniques. While working with clay can be a rewarding and creative process, understanding the intricacies of clay preparation, drying, and firing is crucial to avoid potentially hazardous missteps. Factors such as trapped air, moisture content, and improper thickness when creating ceramic pieces contribute to these explosive mishaps during kiln firing.

| Factor | Description | Prevention Tips |

|---|---|---|

| Trapped Air | Air bubbles can form in the clay when it is improperly wedged or modeled. | Ensure thorough wedging and compress clay well during shaping. |

| Moisture Content | Excess moisture left in the clay can create steam during firing, leading to explosions. | Allow pieces to dry slowly and evenly; use a kiln preheat or candling process. |

| Improper Thickness | Inconsistent thickness can lead to uneven drying and firing. | Craft pieces with uniform thickness and use proper sculpting techniques. |

The Sneaky Culprit: Trapped Air

Trapped air within clay is often an invisible adversary, silently waiting to wreak havoc in the kiln. It’s like an undercover agent, but rather than gathering intelligence, it collects potential for an explosive release. The key to neutralizing this threat is thorough wedging—a seemingly simple step that can make all the difference. When you knead the clay effectively, much like working dough for bread, you push out air bubbles and ensure a more uniform texture. Remember, just like a secret ingredient in a recipe that makes all the difference, consistent and comprehensive wedging is the cornerstone of a well-prepared masterpiece.

Moisture Woes: Achieve the Right Balance

Moisture is another tricky opponent on the path to perfect pottery. Excess moisture trapped in the clay transforms into steam during firing, and this is the main catalyst for those dreaded explosions. The drying phase isn’t something to rush; it’s the mindful pause that ensures success. Allow your clay creations to dry naturally, favoring a slower pace. Using a fan can help, provided it’s not blowing directly on the piece, which could cause uneven drying. The smart potter respects the art of patience, utilizing candling in the kiln to gently coax out the last remnants of moisture. Think of it as the ritual that prepares your art for its fiery final trial.

The Art of Thickness: Consistency is King

Shaping clay with inconsistent thickness is like trying to bake cookies where some are thicker than others—they simply won’t bake evenly. The thicker areas tend to retain more moisture, leading to uneven drying, risking uneven firing, and, ultimately, costly breakage. Crafting with deliberate attention to thickness isn’t merely about aesthetics; it’s about ensuring structural integrity. Use calipers and other measurement tools to regularly check your work. Aim for a uniform thickness, and if you must vary it, transition gradually to minimize stress points. Each piece, when evenly crafted, stands a significantly greater chance of emerging unscathed from its fiery trial.

Ready for Your Creative Adventure? Share your clay triumphs or kiln conundrums in the comments. What are your top tips for avoiding explosions in the kiln? Let's swap stories and strategies! For comprehensive strategies and training on kiln safety, refer to this Kiln Safety Training Program or gain more insights on Kiln Safety.

Get Inspired! Explore our recent articles for more tips and creative inspiration.

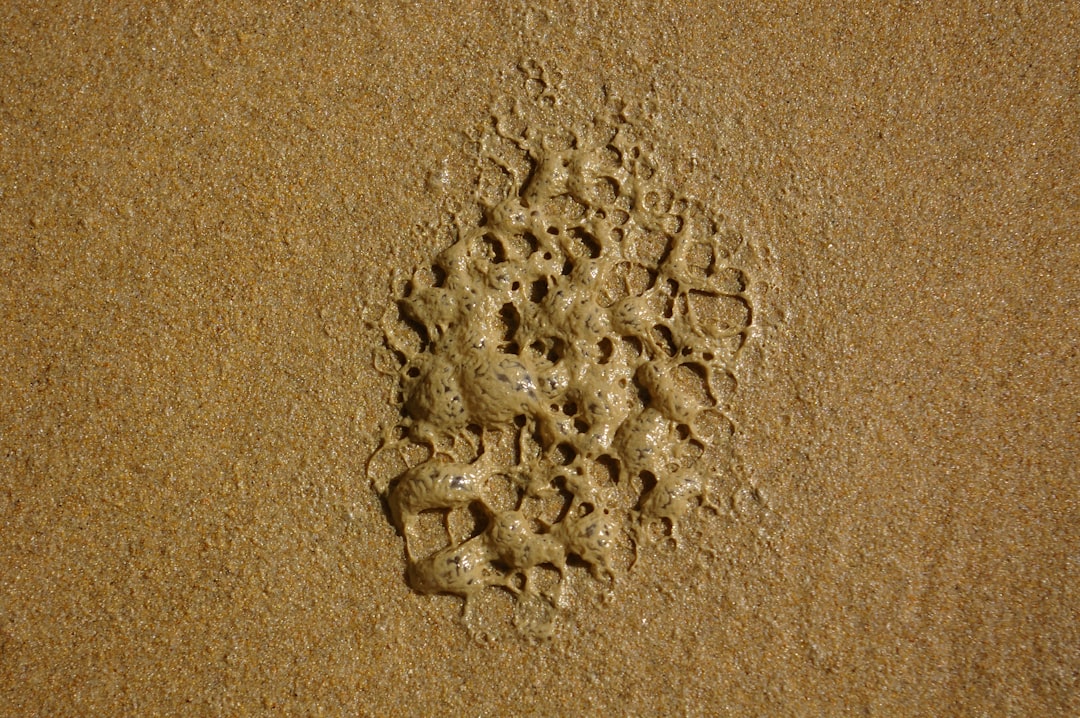

Clay Furnace Explosion

What causes clay to explode in the kiln is a question many potters face, often due to the material’s natural properties interacting with improper techniques. While working with clay can be a rewarding and creative process, understanding the intricacies is crucial. In the video “Clay Furnace explosion” by MrCheatAk, you can see what happens if you start your furnace without annealing.

How can you prevent clay from exploding in the kiln?

Giving your clay pieces enough time to dry thoroughly before firing is crucial. Proper ventilation and a gradual temperature increase in the kiln help any remaining moisture and gases escape safely. You can also space out your work to ensure even heat flow and avoid overcrowding. By controlling the firing schedule and using a well-maintained ventilation system, you minimize the internal pressure that can lead to explosions.

What causes clay to explode in a kiln?

Excess moisture and trapped air pockets are the primary culprits behind kiln explosions. As moisture converts to steam under high temperatures, it expands and forces its way out. When the clay is overly dense, not wedged correctly, or still damp, the building pressure can cause the piece to fracture or explode. Thoroughly wedging your clay, shaping it evenly, and allowing it to dry completely are key steps in preventing sudden breakage.

How thick can clay be without exploding?

A safe guideline is to keep your clay walls and forms under 25mm in thickness. Thinner walls dry faster and provide fewer places for moisture or air to hide. If you must work with thicker sections, consider hollowing them out or using vents and holes to let humidity escape. This not only lowers the risk of damage but also makes your piece lighter after firing.

What causes clay to crack in a kiln?

Cracking often stems from uneven drying or rapid temperature changes. As the clay dries, it shrinks and can pull apart if certain areas dry faster than others. Gradually air-drying before loading the kiln and using appropriate firing schedules helps minimize thermal stress. Properly managing moisture, controlling temperature ramps, and ensuring uniform thickness across the piece all contribute to reducing cracks and deformities.

Understanding the causes behind clay explosions in the kiln is essential for every potter striving to perfect their craft. By paying attention to moisture levels, firing temperatures, and proper ventilation, you can significantly reduce the risk of unexpected mishaps. Embracing these best practices not only safeguards your work but also enhances the overall quality and beauty of your ceramic pieces.

Stay Connected

I'm always excited to share more tips and insights about pottery and kiln firing techniques. If you enjoyed this post and want to explore similar content, be sure to follow us on Instagram. Let’s continue this creative journey together!