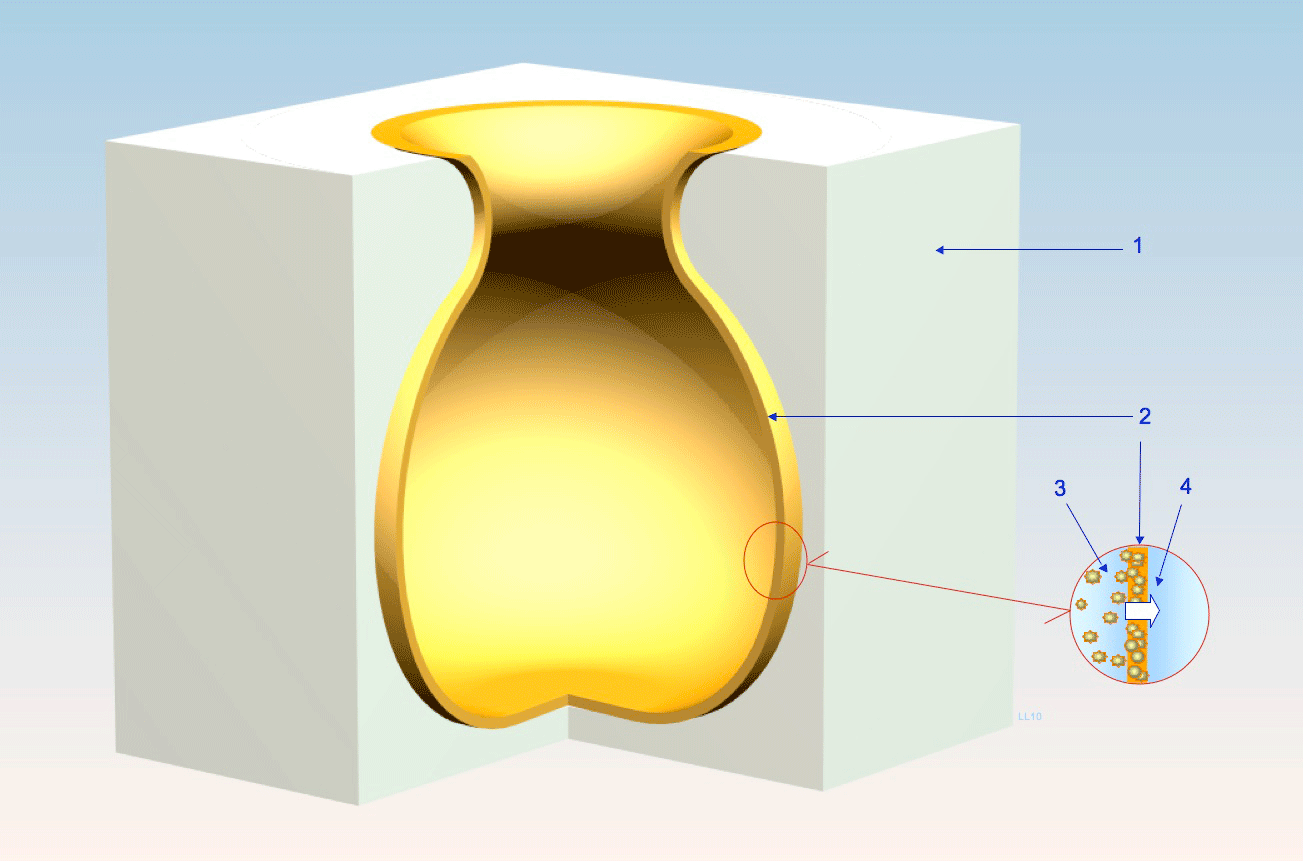

Slip casting is a fascinating and versatile ceramic shaping technique where liquid clay, known as slip, is poured into a plaster mold, allowing the moisture from the slip to be absorbed into the mold walls. This leaves a layer of clay that eventually hardens and can be removed, resulting in a finely detailed form. This process not only allows for intricate designs but also makes it possible to produce multiple versions of the same form, ranging from simple functional items like cups and bowls to complex decorative pieces. Below, we delve into the key advantages and applications of slip casting to better understand its role in both artisanal and commercial ceramic production.

| Advantage | Description |

|---|---|

| Precision | Enables detailed and intricate designs due to the mold’s precision. |

| Efficiency | Facilitates batch production, allowing for multiple replicas of a design. |

| Versatility | Suitable for creating a wide range of items from functional ware to decorative pieces. |

The Art of Precision in Slip Casting

When it comes to crafting ceramics, the precision that slip casting offers is an artist’s dream. Imagine being able to replicate the most delicate textures, intricate patterns, or complex geometric shapes effortlessly. This technique empowers ceramicists to capture fine details that would be nearly impossible to achieve through traditional hand-building methods. With the use of a well-crafted mold, your creative possibilities become endless. Whether you’re aiming to produce a series of highly detailed sculptures or need consistency in design for functional pottery, slip casting provides a reliable solution.

Efficiency: More Than Just Mass Production

While efficiency often translates to mass production, slip casting offers so much more than just that. It’s about maximizing creativity without sacrificing quality. By using multiple molds, artisans can produce an array of items quickly and uniformly, bypassing the inconsistencies that might arise from other techniques. This process is a boon for those looking to maintain a consistent aesthetic across their ceramic pieces, making it ideal for both small-scale studios attempting to grow and larger commercial operations looking to streamline production. The time saved means more opportunities to experiment with new ideas or perfect existing designs.

Versatility in Design and Application

The versatility of slip casting is nothing short of astonishing. Whether you’re crafting functional ware like plates and vases or pushing the boundaries with avant-garde decorative pieces, slip casting can handle it all. It’s this flexibility that attracts artists who seek to explore new themes and concepts without being held back by technical limitations. Slip casting is adaptable, allowing experimentation with shapes, sizes, and even textures. This adaptability opens doors to creating not just art but innovating useful household items that add character to everyday living.

Why Slip Casting Remains a Popular Choice

Beyond its technical advantages, slip casting continues to hold a cherished place in both artistic and industrial circles due to its balance of artistry and efficiency. For artists and designers, this method offers a means to translate their most ambitious visions into tangible products, while for manufacturers, it provides an efficient pathway to producing high-quality goods. The ability to replicate designs accurately multiple times over without compromise means that the investment in crafting detailed molds pays off with every cast. For a deeper dive into the process, you might find this step-by-step guide to slip casting particularly informative.

Have you experimented with slip casting in your work, or is it a technique you’d like to try? Share your experiences with slip casting, or let us know what interests or surprises you about this versatile method! You can also explore more of our recent articles and content to discover new insights and techniques in the world of ceramics and design.

What is the meaning of slip casting?

Slip casting is a well-loved ceramic-making technique where you pour a liquid clay mixture (called slip) into a porous plaster mold. As the mold absorbs moisture, a clay shell forms along the interior walls. Once the excess slip is drained away, you’re left with a hollow shape ready for trimming, firing, and glazing. It’s a wonderful way to produce consistent, refined pieces—something we’ve been perfecting at The Bright Angle to showcase the elegance of ceramic design.

What are the advantages of slip casting?

A key advantage is its speed and adaptability. You can easily vary the thickness of your pottery by adjusting the slip’s time in the mold, making it ideal for crafting items both delicate and sturdy. Slip casting also lets you replicate shapes with accuracy, so it’s perfect for mass production or for experimenting with multiple design variations without needing to throw each piece manually.

What are the disadvantages of slip casting?

Despite its efficiency, slip casting can require significant setup. You often need multiple plaster molds, which can be bulky to store and handle, especially when producing large quantities. Tight tolerances can be harder to achieve compared to other methods, and because each piece involves pouring, waiting, and draining, the overall workflow can feel repetitive and labor-intensive. Still, for shapes that aren’t easily created on the wheel, slip casting remains a cornerstone technique in modern ceramics.

Slip casting opens up a world of creative possibilities for both amateur and professional ceramicists. Whether you’re crafting intricate dinnerware or sculptural pieces, understanding the nuances of slip casting can greatly enhance your artistic process. Embracing this technique allows you to experiment with shapes and textures that might be challenging to achieve through other methods, making your ceramic projects truly unique and personalized.

Stay Connected

If you found this overview of slip casting helpful, I'd love to keep sharing more tips and inspirations with you! Feel free to follow us on Instagram to stay updated on the latest ceramic techniques, project showcases, and behind-the-scenes looks at our creative process. Let’s continue this artistic journey together!