What is slip casting? It’s a time-honored ceramics technique that involves pouring a liquid clay mixture, known as slip, into plaster molds to create hollow ceramic forms. Often chosen for its ability to produce complex and detailed shapes, slip casting allows artisans to replicate intricate designs and create large batches of uniform pieces efficiently. Originating in ancient China and evolving over centuries, this method remains fundamental in both artistic pottery and industrial ceramics.

| Slip Casting Steps | Key Details | Considerations |

|---|---|---|

| Materials Needed | Plaster Mold, Rubber Bands, Porcelain Slip | Ensure molds are clean and dry for best results |

| Preparing the Mold | Align mold halves and secure with bands | Prevent leakage by ensuring tight mold closure |

| Pouring and Draining the Slip | Fill mold, wait for thickness, drain excess | Monitor thickness for desired wall dimensions |

| Drying and Releasing | Dry for 2 hours, gently remove piece | Handle with care to avoid deformations |

Unveiling the Slip Casting Process

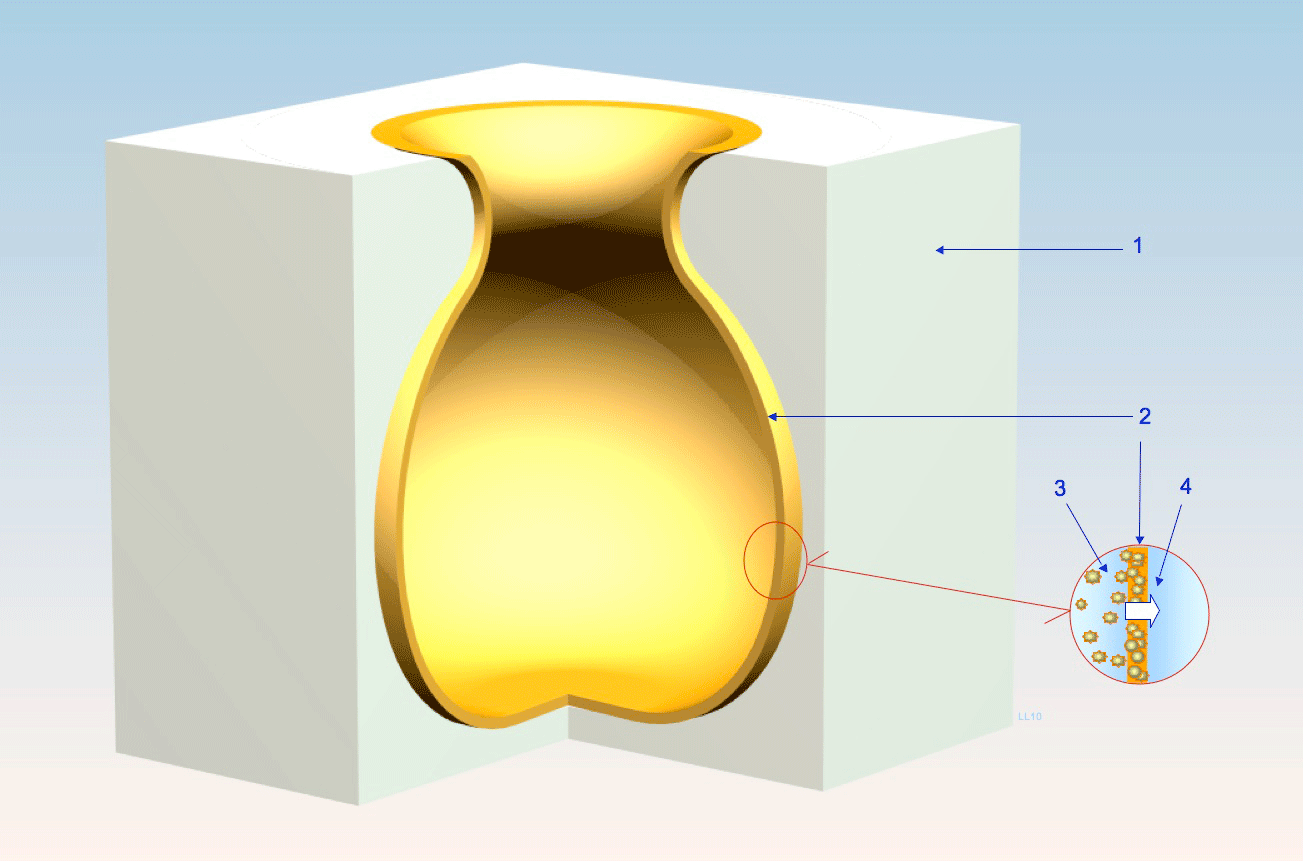

Slip casting transforms liquid clay, or slip, into stunning ceramic forms. This method caters especially to pieces boasting intricate details and complex shapes, such as cups, bowls, and even sanitary ware. By leveraging the absorbent capacity of plaster molds, slip casting allows artisans to effortlessly replicate detailed designs.

The Essentials: Materials and Preparation

Just like any art form, slip casting starts with a robust toolkit. You’ll need plaster molds, elastic bands to keep the molds intact, and a good-quality casting slip—usually a porcelain variant. Before you start, ensure your molds are dry and clean. This preparation is crucial to avoid imperfections or leaks. Align the mold halves precisely and secure them with rubber bands to prevent any slip from escaping during the process. For a more in-depth understanding of these techniques, consider this step-by-step guide to slip casting.

The Art of Pouring and Timing

Pouring the slip into the mold is perhaps the most satisfying part. It’s important to keep an eye on the timing to achieve the desired wall thickness. Most ceramics require the slip to sit for about 20 minutes, letting the plaster mold closely absorb water from the slip, forming a clay layer within. For larger or more detailed pieces, this time may vary. For instance, some sanitary ware components can take up to an hour in the mold.

Once your desired thickness is achieved, gently drain the excess slip. The mold will need to rest afterward, allowing the piece to firm up enough for removal.

Finishing Touches and Removal

After around two hours, the piece usually reaches the right consistency for removal from the mold. This stage demands a gentle touch. Carefully dismantle the mold halves and extract your creation. Any sharp seam lines or excess clay can be trimmed away with a knife or sponge, refining the shape before letting it dry completely. Once fully dried, these pieces are fully prepped for bisque firing, where they become durable ceramic ware. Explore more about mold making and casting processes from Bennington College’s course offerings and Columbia University’s special topics.

Benefits and Challenges

The versatility of slip casting allows for precision and uniformity, making it an essential technique for both industrial producers and individual artists. It provides the ability to create stunningly detailed pieces and reproduce them consistently. However, the process requires attentive monitoring, from slip consistency to mold handling, to minimize defects like over/under-deflocculation or shrinkage. A detailed exploration of the ceramic lessons on slip casting can offer valuable insights into these technical nuances.

This method also opens up the potential for innovation. As studios like The Bright Angle demonstrate, combining 3D printing technology with traditional slip casting can revolutionize how molds and intricate designs are achieved. This adaptability keeps slip casting relevant in modern ceramics, offering both challenges and opportunities for creative expression.

How have your experiences with slip casting been? Any tips or strategies that have worked wonders for you? Share your insights—I’d love to hear your stories! For more recent updates on ceramic arts, visit our blog.

Learn Slip Casting with Outpost Pottery

To deepen your understanding of slip casting, watch Outpost Pottery’s “Learn Slip Casting in 3 Minutes with this Step-by-Step Tutorial.” This video offers a clear and concise guide to the time-honored ceramics technique, demonstrating how to pour liquid clay into plaster molds to create detailed and complex ceramic forms.

What is the slip casting process?

Slip casting is a popular ceramic formation method that allows you to craft intricate shapes from a liquid clay mixture, known as slip. This slip—made of fine ceramic particles suspended in water—is poured into a plaster mold, where the water is gradually absorbed, leaving a solid layer of clay that mirrors every detail of the mold. Porcelain is often the material of choice in slip casting for its durability and refined finish, making it ideal for everything from cookware and dishware to artistic décor.

What are the advantages of slip casting?

With slip casting, you can repeatedly produce identical, high-quality ceramic pieces in large quantities. The process excels at capturing detailed designs while maintaining consistent wall thickness, helping you achieve complex shapes without the need for high-temperature melts. This method is not only efficient and cost-effective but also highly versatile, giving both hobbyists and professionals the flexibility to create a wide variety of functional and decorative ceramics.

Is slip casting considered handmade?

Although molds are central to slip casting, skilled artisans still play a hands-on role in creating and finishing each piece. Mold-making itself requires artistic expertise, and many slip-cast designs are assembled from multiple cast elements, then refined by hand. As a result, each piece retains a distinctive handmade quality, blending the precision of molds with the personal touch of the ceramic artist.

How many times can you use a slip cast mold?

The number of casts you can get from a slip mold depends on its level of detail and overall condition. In general, a high-quality mold can handle anywhere from 50 to 80 casting cycles before wear and tear set in. More intricate designs may shorten a mold’s lifespan, while simpler ones often last longer, making proper care and storage essential for extending usability.

Whether you’re a seasoned potter or just starting out, slip casting offers a versatile and rewarding method to bring your ceramic visions to life. Its precision and ability to handle intricate designs make it a favorite among artists looking to push the boundaries of their craft. Embracing this technique can open up a world of creative possibilities and elevate your ceramic projects to new heights.

Stay Connected

If you enjoyed learning about slip casting and want to see more of our ceramic projects, follow us on Instagram. We'd love to share our latest creations and inspire your own artistic journey!